Waiting for March|Changrong starts a new journey with the third phase of production

- Categories:News Center

- Author:

- Origin:

- Time of issue:2021-12-24

- Views:0

(Summary description)The third phase of Evergreen is an original core breeding farm with a stock of 2,400 pigs and an annual production of more than 15,000 high quality pure breeding pigs. The construction area of the project is 30,000 square meters, and the project will build 2 mating houses, 2 farrowing houses, 2 breeding houses, 1 nursery house, 1 reserve house and 1 boar house.

Waiting for March|Changrong starts a new journey with the third phase of production

(Summary description)The third phase of Evergreen is an original core breeding farm with a stock of 2,400 pigs and an annual production of more than 15,000 high quality pure breeding pigs. The construction area of the project is 30,000 square meters, and the project will build 2 mating houses, 2 farrowing houses, 2 breeding houses, 1 nursery house, 1 reserve house and 1 boar house.

- Categories:News Center

- Author:

- Origin:

- Time of issue:2021-12-24

- Views:0

The third phase of Changrong is an original core breeding farm with a stock of 2,400 pigs and an annual production of more than 15,000 high quality pure breeding pigs. The construction area of the project is 30,000 square meters, with 2 mating houses, 2 farrowing houses, 2 breeding houses, 1 nursery house, 1 reserve house and 1 boar house.

After the practice of automation and intelligent application in phase I and II, Changrong will iterate and upgrade the intelligent and data application in phase III, which will be a new milestone for Changrong.

Top view of Changrong Phase III

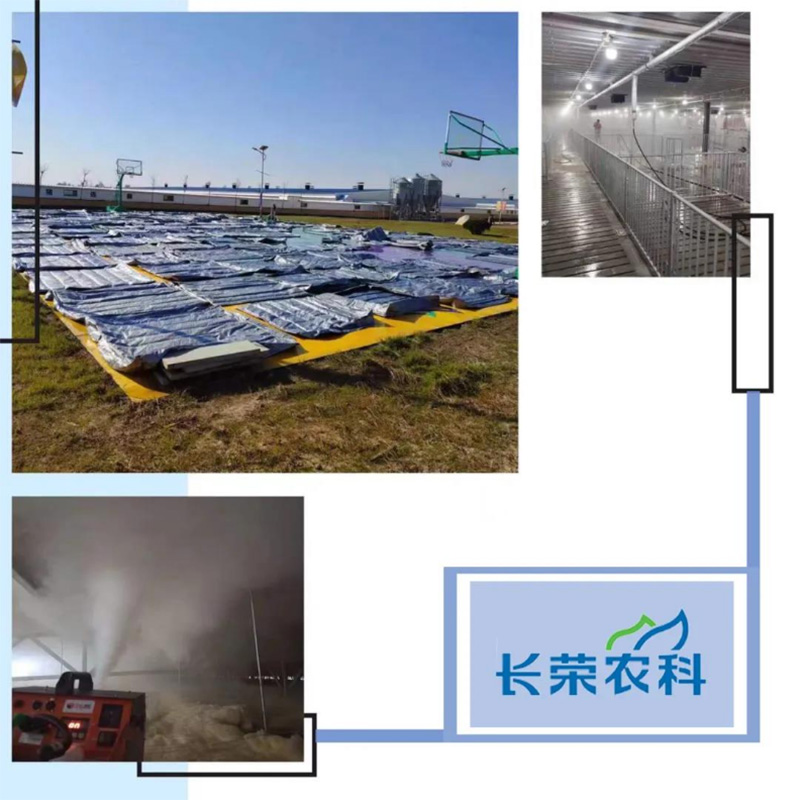

As the New Year is approaching, Changrong Phase III has also made a series of preparations before commissioning. Firstly, the multi-phase decontamination of the whole site was completed. Secondly, the checklist type acceptance was completed. Finally, the normal production scenario was simulated for several times to check and fill in the gaps in time to ensure that every link is running normally.

Effective operation of decontamination work

Intelligent feeding to improve performance

Increasing efficiency and reducing cost is one of the themes of pig industry this year, how to improve the performance of pigs themselves and increase equipment utilization has become a benchmark direction.

The adoption of intelligent feeding management system in the sow stage can help pig managers to improve the feed intake of lactating sows, thus improving their reproductive performance, while reducing feed waste and manpower. The system adopts radio technology, through computer software and a feeder installed on the farrowing bed, it can manage the feeding of each sow during the lactation period according to the age, litter size, body condition and number of piglets of the sow, and use the principle of less food and more meals to improve the actual feed intake of the lactating sow and maximize the lactation of the sow, thus ensuring the good body condition and good breast milk of the lactating sow, thus shortening the estrus interval and increasing the annual litter size of the sows to maximize their reproductive performance.

Smart Feeding Station

Liquid feeding for good intestinal health

With the continuous research and exploration of African swine fever, it is found that paying attention to the intestinal health of pigs is a powerful measure to reduce the risk of non-fever. Pig breeding returns to "nurturing" and promotes growth by nurturing. The system has the following significant advantages: First, it can save 5%-10% of feed and improve the conversion efficiency; second, no dust in feeding, high digestibility and reduce ammonia concentration; third, regular and quantitative feeding, more timely discovery of pig health and uniformity; fourth, reduced feeding costs; fifth, the growth rate of pigs can be increased, 5-7 days ahead of slaughter, which can Greatly improve pig raising efficiency.

Liquid Feeding Stations

Data measurement Precise selection of breeding

As a core breeding farm, Changrong III has strict requirements for key indexes such as genetic performance and growth performance of pigs. The breeding stage adopts the fattening pig breeding growth measurement system, each station can feed 15-20 pigs, which mainly determines the growth information of breeding pigs by accurately measuring the feed intake and weight curve of pigs, so as to determine and evaluate their production performance and reproductive performance. Meanwhile, joint breeding with Hapoel and global breeding data sharing. Provide purebred pig with high quality and high performance to Changrong's cooperative customers

Data measurement

Independent boar station Semen improvement

Changrong III has set up a 100-head boar station with standardized operation from semen collection, dilution, testing, canning and transportation to ensure the quality of each semen is guaranteed and traceable. With high quality semen, Changrong's family farm partners can realize low-cost and high-efficiency genetic improvement of pigs, promote production performance, improve production efficiency, and realize "Happy Pig Farming, Enjoy the Farm" that Changrong always advocates.

Boar station equipment

Small details, big improvements

Changrong III also optimizes in other non-production aspects.

1. The whole farm adopts intelligent water and electricity system, which can accurately account for the cost of each batch of pigs, and at the same time warn the health of pigs in time through the data.

2. Pig counting system is set up, which solves the situation of difficult inventory and large inventory error, thus improving work efficiency.

3. The shower room in and out of the farm adopts the intelligent shower system, which can ensure the staff bathing to reach the preset time and expected effect, and reduce the risk of African swine fever.

4. Enclosed corridors are set up between each area to connect all departments into one whole, eliminating the problem of multiple entrances and exits that cannot be controlled, and at the same time solving the contact with the outside world when the pigs are in circulation.

5. The water used in the whole farm is purified, which can produce 18 tons of purified water per hour, and the purified water can reach the standard of direct drinking, and the drinking water for pigs is of the same standard as the living water.

The third phase of Changrong is the key for Changrong to open the core breeding herd breeding work, and will always put "pigs" first and put people first. With the responsibility of promoting the sustainable development of the industry, we will pay close attention to breeding and efficient production, empowering every partner in the Changrong value chain and jointly promoting the sustainable development of the industry.

All things are ready, we will see you in March!

Scan the QR code to read on your phone

Contact Us

Tel:+86-359-2251195

E-mail:changrong@changrong2009.cn

Add:Room 1609, Wanli Office Building, Xueyuan Road, Yanhu District, Yuncheng City, Shanxi Province

Shanxi Changrong Agricultural Technology Co., Ltd. 晋ICP备19010477号-1

+86-359-2251195

+86-359-2251195

Message

Message